Do you even know what dielectric grease is? I first learned about it from my electrician when I was in the home-building industry. So it made me wonder: should you use dielectric grease on trailer plugs?

I found that dielectric grease is a great product for anyone pulling a trailer. However, many people do not properly use dielectric grease on trailer plugs. Using this product improperly can cause more problems than it will fix. So, knowing how to use this product properly is essential.

There is a lot of sketchy information on the internet about how to properly use dielectric grease on trailer plugs. We want to help you navigate this information easier. In this article, we will help you understand the benefits of dielectric grease.

We will also give you helpful information on how to use dielectric grease on trailer plugs properly.

What Is Dielectric Grease?

Generally, dielectric grease is a silicone-based grease that is a non-conductive insulator and is water and moisture-resistant.

Frequently used in automotive applications, it protects and increases the life of things like lightbulb connections, spark plug boots, and battery terminals. It is also a helpful compound to use on a variety of electrical connections on your travel trailer.

A common misconception about dielectric grease is that it is a lubricant. Okay, technically, it can lubricate things, but that’s not its intended purpose. Dielectric grease on trailer plugs is important for sealing out moisture and preventing corrosion but should not be used as a lubricant for sticky connections.

The high viscosity of dielectric grease allows it to stick to both metal and plastic or rubber parts without dripping or melting into a big mess. That being said, dielectric grease is not designed for really high-heat applications. It is generally safe for use up to 392° F (200° ).

Where Should You Use Dielectric Grease?

Dielectric grease is helpful when used in the proper places on your travel trailer. There are some particular locations on your travel trailer or vehicle where you can gain the most benefit from dielectric grease.

Dielectric grease can be used at many locations on your travel trailer. Anywhere an electrical connection may have some exposure to moisture including:

- The outside of electrical connections located on the exterior of your trailer.

- O-rings and seals for your coaxial cable (TV) connection.

- On the male and female connection surfaces for the trailer plug

- Tops of battery terminal connections

- At joints between the wire and plug where moisture could seep into the wire.

- Spark plug boots for your tow vehicle

- Exterior light bulbs.

Remember, dielectric grease is used as an insulator, not a conductor or lubricant. If you need a product to improve a connection or act as a lubricant, you will want to find a different product.

Do You Put Dielectric Grease On Electrical Connectors?

This is a subject that has sparked a lot of conversation in the RVing community. Some people love dielectric grease and think it is the best thing ever. While other folks who have had challenges with dielectric grease think it is an awful product.

The idea is to use dielectric grease on and around the area of an electrical connection. The metal connectors themselves do not need to be coated. Keeping moisture from entering the connection and coming in contact with the connectors is the key.

Some people claim to have had issues with dielectric grease that has been applied to metal connectors in plugs and caused corrosion. Again, keeping the moisture away from the connectors is the purpose. Not necessarily to coat the connectors. With a proper external seal, the metal connectors should be safe.

How Do You Apply Dielectric Grease?

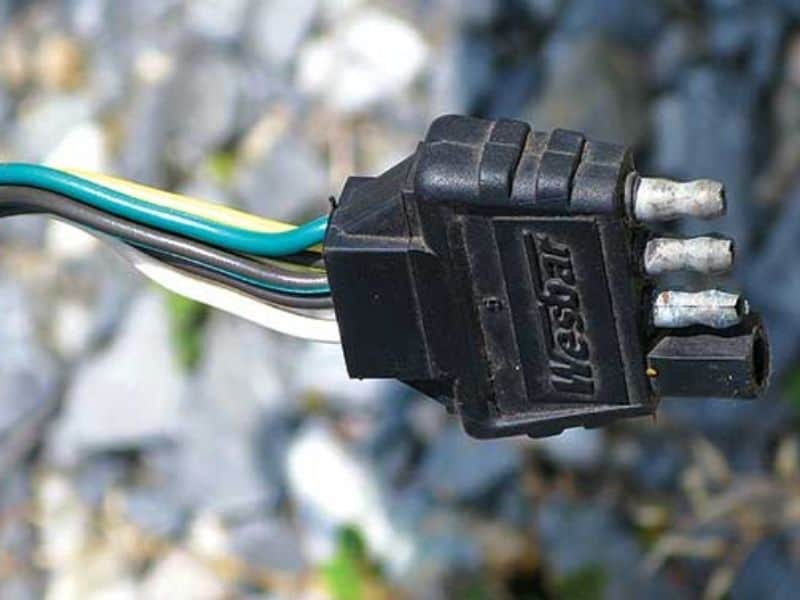

When it comes to trailer plugs, the application of dielectric grease is pretty simple. A small amount of the product is applied to the inside edge of the female side or the outside of the male side before making the connection.

When applying, the small amount of grease on the connectors it will be dispersed out when the connection is made. This ensures metal to metal contact of the connectors.

When used properly, the grease squishes out of the socket leaving a good electrical connection while creating a watertight seal. You can also apply some additional grease after the connection is made. Don’t forget to use some on the end of the plugs where the wire harness enters.

You do not need to use a lot of dielectric grease to get a good seal. Used properly, it is very effective at resisting moisture.

However, if used improperly, dielectric grease can actually prevent the prongs and sockets from making a good electrical connection.

Should You Use Dielectric Grease On Trailer Plugs?

You should absolutely use dielectric grease on trailer plugs. It can be especially helpful if you are planning to travel to a location that has a lot of precipitation or if you are traveling during the winter.

Dielectric grease on trailer plugs will ensure that the connection between your trailer and tow vehicle doesn’t short out and stop working. If your trailer plug shorts out while traveling, your trailer will not have the proper safety lights required for safe operation (brake lights and tail lights).

Moisture that enters the plug can sit inside and corrode the metal connections on the plug. This will result in you having to replace your trailer plug.

The key to using dielectric grease on trailer plugs is to use it properly. As mentioned previously, a little grease goes a long way. Make sure that you do not use so much grease that you goop up the outlet and inhibit the flow of electricity from the outlet to the plug.

Another good practice before using dielectric grease on your trailer plug is to make sure that the surfaces are free of dirt. Dirt can stick to the dielectric grease and make a poor seal.

Also, make sure that you are using a silicone-based product. Silicone greases are hydrophobic and have a high melting point, so they naturally repel water and they won’t melt if the weather gets warm.

Is Vaseline The Same As Dielectric Grease?

Vaseline or petroleum jelly is not the same as dielectric grease. Before silicone grease products were invented (pre-1960), Vaseline or petroleum jelly was used to create water-proof seals on electrical components. It was the best product at the time and didn’t harm the electrical connection.

Petroleum jelly is not an ideal product for electrical connections because it has a low melting point, causing it to become liquid and messy at a fairly low temperature.

Petroleum jelly can also damage rubber and plastic parts. Dielectric grease will not harm plastic or rubber parts, so it is a better choice than Vaseline or petroleum jelly.

Should You Spray WD-40 On Trailer Plugs?

This is another subject that has a lot of controversy on the internet. However, using WD-40 on trailer plugs is not recommended. Not because it is an ineffective product but because it is not the proper product to use on trailer plugs.

As a petroleum product, WD-40, over time, will damage the rubber parts of your trailer plug. Though it is a water-resistant lubricant, the chemical reaction between the petroleum and rubber can cause the components to fail.

If you are in a pinch, WD-40 might be OK. However, make sure that you use a good electrical connection cleaner as soon as possible to remove the lubricant. This will help you avoid any potential damage to the rubber and plastic parts of your trailer plug.

What’s The Best Thing To Use On Trailer Plugs?

If you are looking for products to use on your trailer plug, whether it is to create a protective seal or to clean or lubricate your trailer plug, silicone-based products are always the best.

Though silicone-based products are ideal for your trailer plug, if used improperly, they can be as problematic as other products. Make sure that you are following the instructions for the product.

If you are having a difficult time making a good connection between your trailer and tow vehicle, you should take some time to clean the connection with a silicone-based electrical connection cleaner.

This will remove any corrosion or dirt from the plug, and help the parts move together smoothly. Trailer plugs are subject to lots of moisture and road grim that will eventually cause issues if you don’t take the time to clean and protect the plug.

4 FAQs About Dielectric Grease

1. What is dielectric grease made of?

Today, most dielectric greases are made from silicone or silicone-based products with a thickener. Silicone is ideal in electrical applications because it does not conduct electricity but provides non-reactive insulation for electrical parts.

Many people think that silicone grease is made of silica and is, therefore, an abrasive product. This is not correct. Some dielectric greases will have silica as a component of the thickening agent, but the quantities are so small and will not add an abrasive quality to the grease.

2. Where do you use dielectric grease?

Dielectric grease is typically used on electrical connections to protect against moisture or corrosion. On your travel trailer, this can include the trailer plug, exterior electrical outlets, battery connections, coaxial cable connections, and even your shore power connection.

3. Does dielectric grease affect conductivity?

Yes, dielectric grease can affect conductivity. Dielectric grease is intended to be an insulator for electrical connections. If used improperly, an excess of dielectric grease can coat outlet parts and inhibit the electrical current from flowing between the outlet and the plug. To avoid this potential problem, use dielectric grease in moderation.

4. Should you use dielectric grease on trailer plugs?

Because your trailer plug is exposed to moisture, particularly when traveling on rainy days or on wet roads, dielectric grease is a great product for trailer plugs. A small amount of dielectric grease on trailer plugs will ensure a water-tight connection that will not short or corrode over time.

Final Thoughts About Using Dielectric Grease On Trailer Plugs

Though the use of dielectric grease on trailer plugs is a bit of a controversial topic within the RV community, it is a useful product and has plenty of applications for both your travel trailer and tow vehicle.

Beyond your trailer plug, dielectric grease can be helpful for protecting other electrical connections from moisture and corrosion.

Using dielectric grease on trailer plugs is a maintenance practice that many travel trailer owners should consider. When used properly, dielectric grease can be a helpful tool for ensuring a good connection between your trailer and tow vehicle.

Related Reading:

– How To Release A Trailer Hitch That’s Stuck On A Ball

– How To Stop A Trailer Hitch From Squeaking

– Should You Grease Your Trailer Hitch Ball Or Not?

– How To Replace A 7-Pin Trailer Plug

About the Author:

Jason Gass is a full-time freelance writer and part-time RVer whose goal is to share great stories around a campfire with good friends.

When he’s not working, he spends most of his time camping, searching for the best breweries, and road-tripping in his teardrop trailer with his wife, daughter, and two dogs.